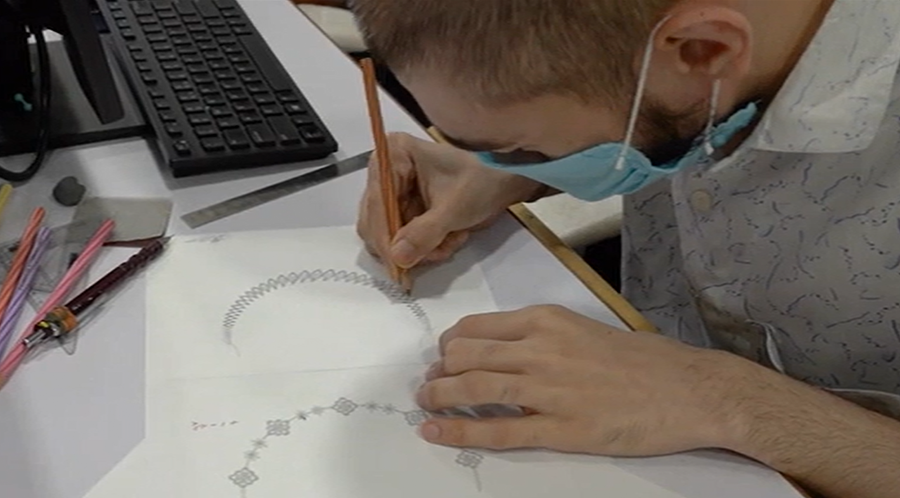

DESIGN

Design team at Kyonik develops new designs based on market requirement and trends. Once a design is conceptualized, it is drawn on paper and then into the system. This process is facilitated through Computer Aided Designing technology. Detailed attention is given to dimensional accuracy of design. A 3-D view of every design is created using CAD before it goes into model making.

DIAMOND ASSORTING

At the diamond assorting department of Kyonik Jewel, professional diamond assorting personnel sort and grade the stones on the basis of colour, clarity, shape and size, in accordance with industry standards.

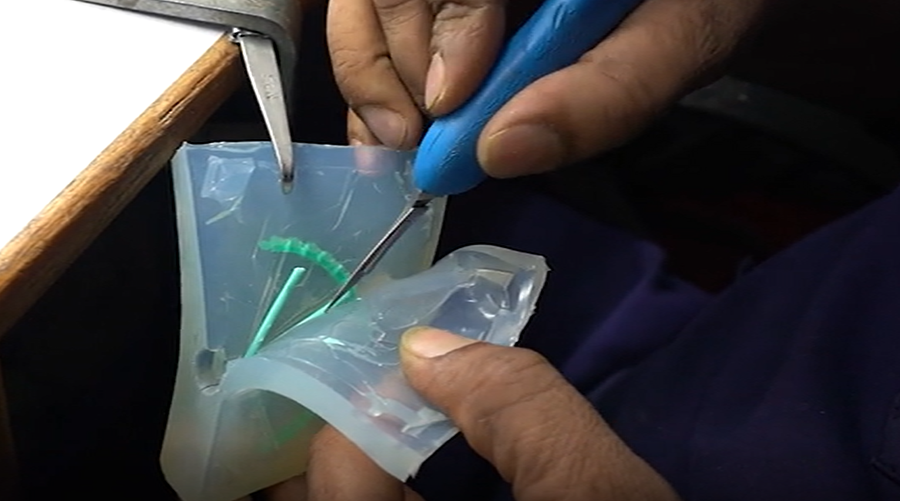

THE MODEL-MAKING

CAD design is transferred on 3D Rapid Prototype system which works on the principle of Direct Light Projection Technology. The resin model is created using 3D RPT system. Resin model is then converted into silver model using casting process. The silver model is a master design and it is used to create the rubber Mould from which all subsequent pieces are made.

THE MASTER MODEL WAX REPLICAS

Master model impression is created by sandwiching it between sheets of rubber and vulcanizing at a high temperature. The rubber mould is carefully sliced open to leave behind the cavity of the model. The Wax is injected into The rubber mould via wax-injecting machine which shoots out wax in a molten state at a pre-set temperature and pressure. Afetr wax cools down, it assumes the shape of the cavity. This wax replica is extracted from rubber mould.

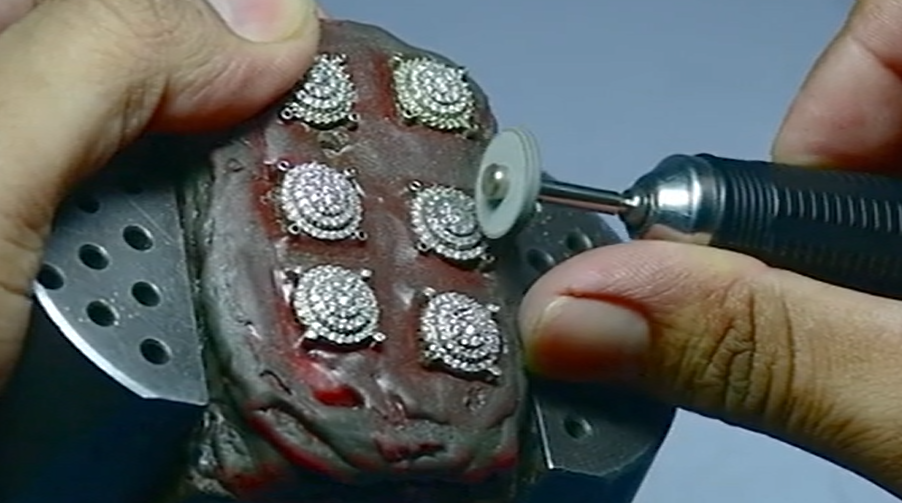

DIAMOND SETTING

CASTING

FINISHING

QUALITY CONTROL